NEWS CENTER

Do you know the advantages and installation of non-demolition floor decks?

2022-12-23

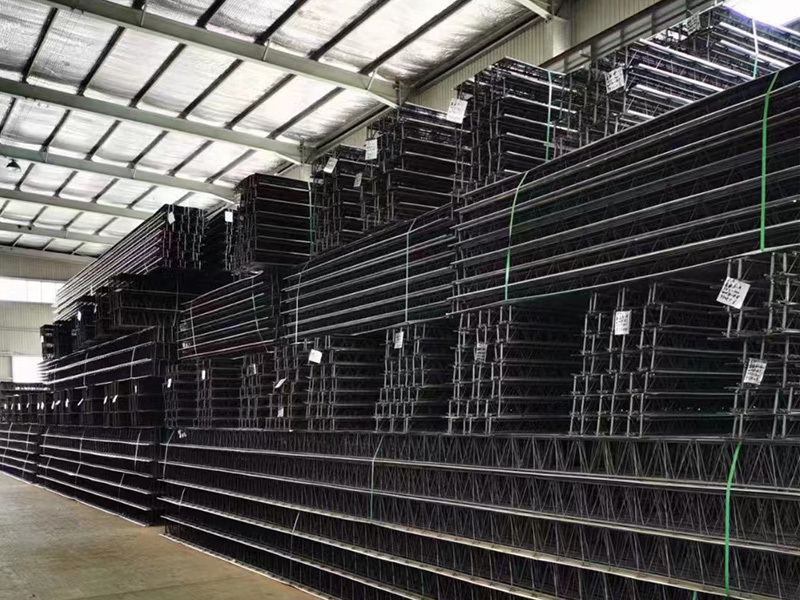

The non-demolition floor bearing plate is a kind of steel bar truss and the non-demolition bottom mold through special connectors or anchor prefabricated connection into a whole, and the use of industrial consumption of a new type of steel bar truss floor bearing plate, in the construction process has the function of formwork, no need to remove the formwork, is a new type of material suitable for the prefabricated building.

No demolition of floor decks

What are the advantages of non-demolition floor decks? Here's an introduction.

1. High level of standardization, large production capacity and low cost. The width of the non-demolition floor deck is unified to 1200mm, the length is customized according to the size of the bay, and the combination device can be cut before laying, with a high degree of standardization, and the research and development of the floor deck assembly line has a high level of automation, less labor, and a single shift can consume 5400 square meters of floor deck, which is equivalent to the production capacity of 6-8 PC laminated board assembly lines, based on the above reasons, the product cost is much lower than that of laminated boards.

2. No need to remove the mold, no plastering, less support. Its bottom slab is the formwork, and the concrete floor slab does not need to be plastered after pouring, and the putty can be scraped directly. Only one support is needed in the middle of the span of the floor deck to pour concrete.

3. The construction speed is fast, there is no post-pouring belt, and the beam reinforcement is convenient for binding. Its main stressed steel bar stops positioning and welding forming on the automatic control consumption line, the steel bar is evenly arranged, the position is accurate, and the construction is fast, which can reduce the on-site steel bar binding workload by about 70%, greatly shorten the construction period, and save costs. The spacing between the upper and lower layers of steel bars and the thickness of the concrete maintenance layer can be abundantly guaranteed, which creates favorable conditions for improving the construction quality of the floor slab. It welds the steel bar into a whole, the overall stiffness is large, the deformation of the floor slab is small when pouring concrete, there is no need to add temporary support in general, and it can accept a larger load in the construction stage, its weight is only 1/3 of the laminated plate, and the whole pile (more than 30 square meters) can be hoisted to the floor when hoisting, because there is no beard tendon, the beam steel bar can be tied first, and there is no need to set up the post-pouring belt, which can save a lot of turnover data and labor, and each layer can save at least 1 day of construction period.

4. The construction quality is controllable. Its bottom plate is only the role of the formwork, which can ensure the integrity of the concrete, the no post-pouring belt can prevent slurry leakage, and its truss reinforcement can ensure the accurate positioning of the stressed steel bars of the upper and lower layers of the floor slab without deformation, and fundamentally deal with the problem of cracking and leakage of the floor slab.

How should the demolition deck be installed? Let's take a look at what follows.

1. First pop up the center line of the steel beam in the paving area, and the center line of the main beam is the control line for laying its fixed position.

2. In the stacking site, the hierarchical partition is cleared according to the material list, and the number is indicated, and the layer, area and number are distinguished, and marked with a marker.

3. When lifting, a special soft sling is used to avoid the demolition of the floor bearing plate as a whole without deformation and part without curling.

4. Use plasma cutting machine or shearing pliers to cut the corners, the ample amount should be controlled within the range of 5mm when cutting and paying, and measures should be taken to avoid slurry leakage when pouring concrete.

5. The connection between the plate and the side plate of the plate is pressed by bite pliers, so that the single piece is connected into a whole board, the side of the plate is spot-welded first, and then the two ends are fixed, and then the bolts are fixed.

Related News

Beijing Lichengda Corrugated Steel Steel Structure Co., Ltd.

Beijing Lichengda Corrugated Steel Stru'cture Co., Ltd.

Head office: No. 668, Wang Hua Village, Huairou Town, Huairou District, Beijing

Branch: Lilanshi Town, Yongqing County, Langfang City, Hebei Province

Quick Links

Follow us

Message

Message  tlxs1472@163.com

tlxs1472@163.com 18610556803

18610556803