NEWS CENTER

Introduction to the advantages and maintenance points of floor deck trusses

2022-12-19

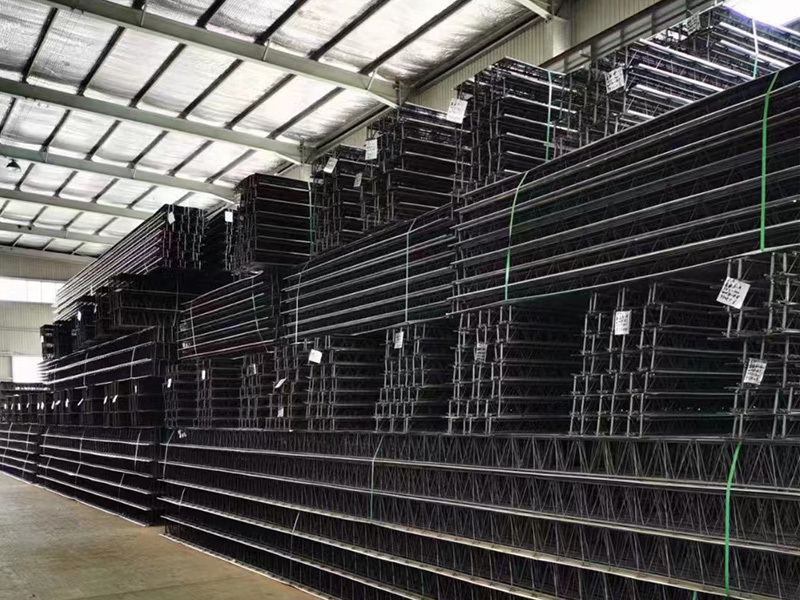

The floor deck truss, also known as the steel bar truss formwork, is a composite structural system that processes the main stressed steel bars in the floor slab into a steel bar truss with special equipment in the factory, and then welds the floor deck truss and galvanized steel plate into a whole. In the construction stage of the structural floor slab, the system replaces the construction template with galvanized steel plate, and the truss structure composed of steel bar welding in the structure bears the concrete weight and construction load of the floor slab, and after pouring concrete, it forms a reinforced truss concrete floor slab, bears the application load in the application stage, and is currently widely used in multi-storey workshops, multi-storey, high-rise, high-rise steel structure buildings, various irregular floors, various prefabricated panels, high-speed railways and other structures and construction categories.

What are the advantages of floor deck trusses? Here's an introduction.

First, in terms of the cost of investment, the materials it uses not only have good performance, but also the price is very affordable, and its plasticity in use is strong, and it can be adjusted according to different construction environments and needs, so it is very convenient.

Second, this type of it has good strength, the welding between the parts is also very tight, so it will not break in the application, and its fire resistance and corrosion resistance are also very good compared with other plates, and the safety is also higher in the application of theory.

3. The floor bearing plate truss has a very good compressive capacity, so it is not easy to deform in the application, and the arrangement order of its steel bars is very neat, and it can be evenly stressed at the time of use, and has a good seismic effect.

Fourth, this type is also more convenient in the process of transportation, and there are no strict restrictions on the construction environment, so it is also very convenient to install, which can effectively reduce the input of manpower and material costs.

The floor deck truss has strong corrosion resistance, can conform to the complex building appearance, and can make boards on site, so the length of the plate is not limited by the transportation pleading, and the length of the board is longer, so as to ensure that a roof panel can exceed the entire roof, reduce lap joints, and also reduce the possibility of water leakage. Let's take a look at what follows.

1. Maintenance film: In order to prevent scratches during transportation and installation, the manufacturer has a layer of maintenance film on the surface of the product, and after the installation is completed, the maintenance film should be torn off as soon as possible, and it is recommended that the maintenance film needs to be removed within 6 weeks from the date of completion of installation.

2. Surface scratches: If during installation, it presents small surface scratches, due to the self-healing nature of its surface, a new blunt surface layer will be regenerated, but if the scratches are deep and wide, it is necessary to consider replacing the plate.

3. Grease and dust: During installation, grease and dust accumulate on its surface, which can be gently wiped off with a clean and monotonous cloth, do not wipe it hard or use cleaning products, and dust can be naturally washed away by rain.

4. Fingerprint prints: When they are applied to the curtain wall, attention should be paid to the problem of fingerprints, to remove them, mineral oil is required, of course, in order to fundamentally prevent fingerprints, wear cotton gloves when installing.

Related News

Beijing Lichengda Corrugated Steel Steel Structure Co., Ltd.

Beijing Lichengda Corrugated Steel Stru'cture Co., Ltd.

Head office: No. 668, Wang Hua Village, Huairou Town, Huairou District, Beijing

Branch: Lilanshi Town, Yongqing County, Langfang City, Hebei Province

Quick Links

Follow us

Message

Message  tlxs1472@163.com

tlxs1472@163.com 18610556803

18610556803