NEWS CENTER

Truss floor deck dry goods sharing, one minute to take you to understand

2022-11-29

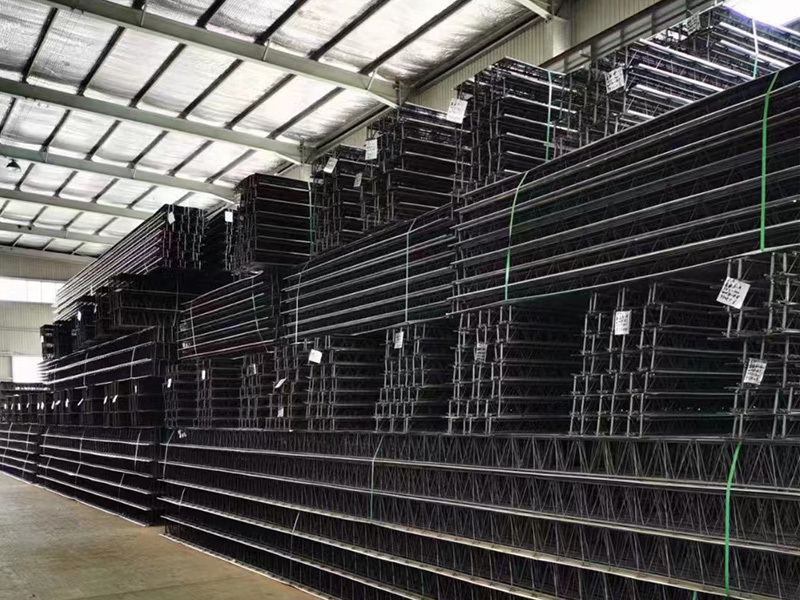

Now almost all construction projects are indispensable to the truss floor deck, the construction of any building is indispensable to the participation of the floor slab, in addition, the application of the truss floor deck in the construction of the power plant is also very common, the truss floor deck can be used as a template in the construction, and can also replace the tensile steel bar in the use stage, combined with the concrete slab to form an integral structure, the floor slab will also be called the floor slab (or composite floor slabs).

Truss floor deck has the advantages of light weight, high strength, large bearing capacity, good seismic performance, fast construction, safety and environmental protection, etc., can be used as a part of the structural strength, reduce the amount of steel bars, clean appearance, etc., due to its technical economy, not only widely used in wineries, power plants and other industrial enterprise buildings, but also widely used in civil buildings.

The truss floor deck is a composite floor slab load-bearing plate welded by a steel bar welded truss skeleton and a profiled steel plate, which is composed of upper chord steel bar, lower chord steel bar, web steel bar, bottom plate and horizontal support steel bar.

What is the processing process of truss floor deck? Let's take a brief look at it with you.

1. Straightening of steel bars: The incoming steel bars are straightened with a straightening machine to ensure the processing quality of the truss plate.

2. The steel truss is assembled and formed, and the length of each truss is cut and welded according to the actual requirements of the project.

3. Processing and forming of the steel plate of the bottom die: the galvanized steel plate of the incoming material is pressed to improve the overall stiffness of the bottom plate and folded.

4. Component assembly: The overall welding assembly of the steel truss and the bottom plate adopts flash butt welding.

5. Carry out quality inspection, and the steel truss floor slab material leaves the factory.

The difference between truss floor deck and ordinary floor slab, let's take a look at it with Xiaobian.

1. The truss floor bearing plate bearing plate itself has a steel truss to bear most of the stress, so that we can use a thinner galvanized bottom plate, reduce the material cost of the galvanized bottom plate, and also greatly reduce the amount of steel binding on site.

2. The span of the truss floor deck is larger than that of the ordinary floor slab, which can greatly reduce the temporary support on site and make the construction environment safer, thereby greatly shortening the construction period of the truss floor deck, reducing labor costs, shortening the construction period, and winning economic benefits in advance.

3. There is no steel truss for ordinary floor slabs, but they can be superimposed during transportation, which is not easy to deform and has low transportation costs.

4. From the price point of view alone, the price of ordinary steelless truss floor slab is lower than that of truss floor bearing plate, but ordinary floor slab still needs to be tied to the site with steel bars, and the amount of steel bar binding is greater than that of steel truss floor slab, which increases the construction period and a large number of steel bar binding, and also increases labor costs.

The role of the two is different in different use needs, so Xiaobian recommends that you choose according to your own needs.

Related News

Beijing Lichengda Corrugated Steel Steel Structure Co., Ltd.

Beijing Lichengda Corrugated Steel Stru'cture Co., Ltd.

Head office: No. 668, Wang Hua Village, Huairou Town, Huairou District, Beijing

Branch: Lilanshi Town, Yongqing County, Langfang City, Hebei Province

Quick Links

Follow us

Message

Message  tlxs1472@163.com

tlxs1472@163.com 18610556803

18610556803