NEWS CENTER

What is the construction sequence of truss floor decks in one minute

2022-11-23

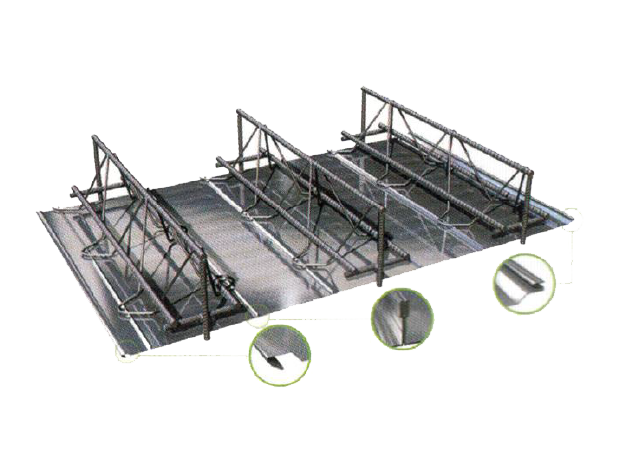

The truss that is connected by resistance spot welding is called a steel bar truss with a steel bar as an upper chord, a lower chord and a web member, and a composite load-bearing plate that is connected into a whole by resistance spot welding with a steel bar and the bottom plate is called a truss-type floor bearing plate.

The truss type floor deck plate realizes mechanized production, which is conducive to the uniform arrangement and spacing of steel bars, the uniform thickness of the concrete protective layer, and the improvement of the construction quality of the floor slab, and the prefabricated steel truss floor slab can significantly reduce the amount of on-site steel bar binding, speed up the construction progress, increase the construction safety guarantee, realize civilized construction, assemble the template and the connector is easy to disassemble, can be reused many times, save steel, meet the national energy conservation and environmental protection requirements, and the products independently developed by the steel structure are equipped with automated production equipment, Greatly improve labor productivity, effectively reduce the cost of products, has been prepared product manufacturer standards, design manuals, joint structure atlases and construction manuals, the product has passed the testing of Zhejiang University Civil Engineering Testing Center, and has been applied in a number of projects, its performance can meet the bearing capacity and deformation requirements of cast-in-place reinforced concrete floor slabs.

Construction sequence of truss floor deck:

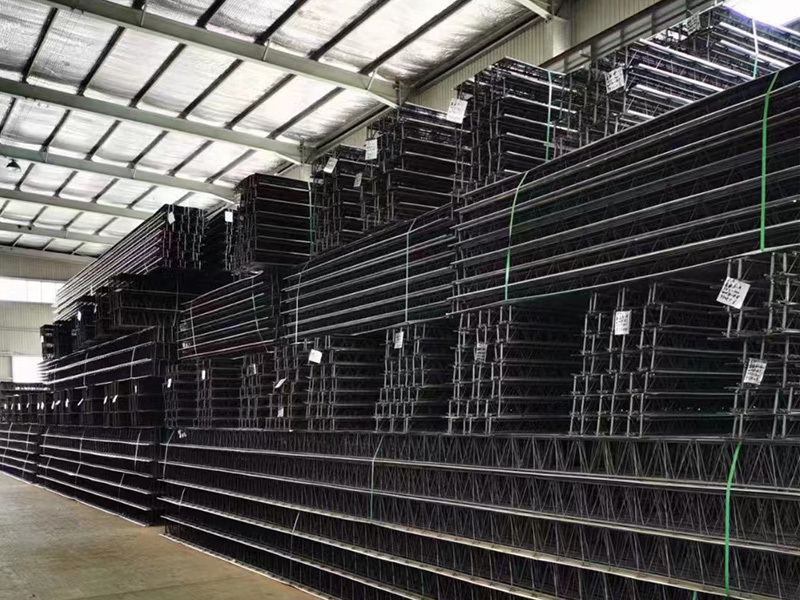

1. Truss floor deck moving in: do a good job of hoisting work, arrange the moving in and placing routes.

2. Truss floor deck hoisting and temporary installation: prepare before hoisting, install supports, draw a baseline on the steel beam, prepare hoisting parts, and take safety measures to protect.

3. Installation of truss floor deck: (1) installation according to the design plan; (2) The edge adjustment of the steel truss: the edge deformation generated during transportation should be adjusted to avoid the loose buckle in the later construction; (3) Align the reference line, install the block plate, install other plates in turn, and the hook connection between the plate and the plate should be tight, so as to ensure that there is no slurry leakage when the concrete is poured, and then use the non-standard plate to finish; After the truss type floor bearing plate is in place, the vertical stressed steel bar should be welded with the steel beam immediately, and the steel beam should be spot welded along the width direction of the floor slab;

4. Stud welding: After the construction of the steel truss plate is completed, the steel structure unit welds the end beam surface with studs, fixes the truss plate, and connects the beam plate into a whole.

5. Touch the board during installation;

6. Additional reinforcement works and pipeline laying;

7. Rebar binding;

8. Pour concrete on site.

Truss floor deck is widely used, and its quality is related to people's life safety, so what inspection needs to be carried out before the truss floor deck is completed and used?

We can test it from its aspects, for example, the size of the truss floor deck needs to meet the requirements of the building, especially whether the floor slabs used in each part of the building meet the design requirements of the drawings, and then see whether the lap length of the vertical steel bar and the steel beam on the steel beam meets the design requirements, and the cutting position of the plate edge and the special-shaped must ensure that there is no slurry leakage, when we use the truss floor deck, its quality is also related to the preservation environment, for example, when we preserve, we must be placed in a dry and ventilated environment, In this way, its quality can be prolonged.

Related News

Beijing Lichengda Corrugated Steel Steel Structure Co., Ltd.

Beijing Lichengda Corrugated Steel Stru'cture Co., Ltd.

Head office: No. 668, Wang Hua Village, Huairou Town, Huairou District, Beijing

Branch: Lilanshi Town, Yongqing County, Langfang City, Hebei Province

Quick Links

Follow us

Message

Message  tlxs1472@163.com

tlxs1472@163.com 18610556803

18610556803