NEWS CENTER

The comprehensive advantages of steel truss floor deck are shared

2022-11-01

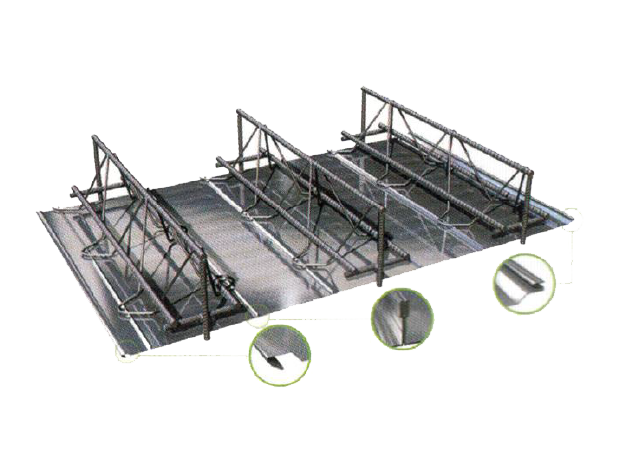

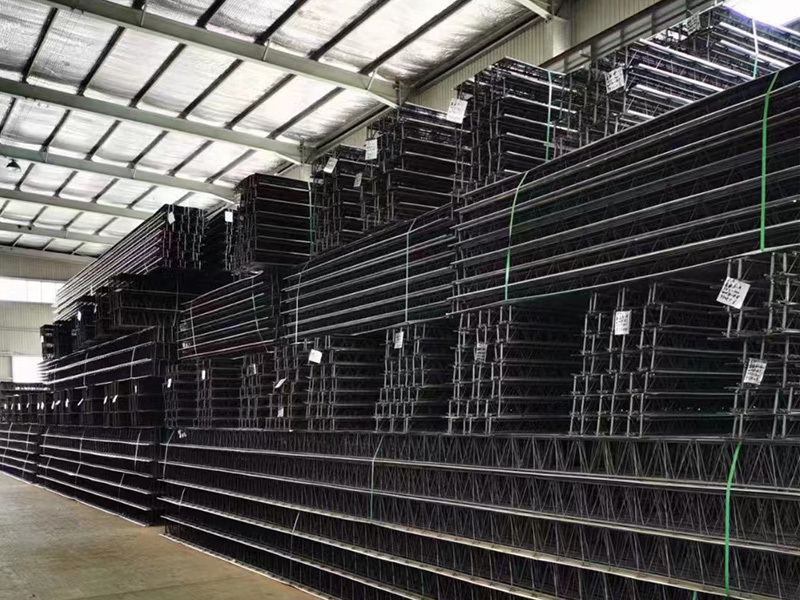

The steel truss floor deck is a composite formwork that processes the steel bar into a steel truss in the factory, and welds the steel truss and the galvanized profiled steel plate into a whole. In the construction phase, the steel truss floor deck can be laid directly on the beam with the construction load, and the concrete can be poured through a simple steel bar project. Because it completely replaces the role of the formwork, the erection and dismantling of the formwork are reduced, and the construction efficiency of the floor slab is greatly improved.

Reinforced truss floor decks

The comprehensive advantages of steel truss floor deck are reflected in the following aspects:

1. Economy:

1. Material selection: The requirements for the thickness of the substrate (0.4 or 0.5), galvanizing amount (120g/m2) and strength (Q23B) are lower than those of other floor slabs. The utilization rate of galvanized sheet is more than 94%;

2. The truss height and reinforcement can be adjusted to adapt to the span of the large slab (to the span of 4.6m and the continuous span of 5.2m), saving construction costs;

3. It greatly shortens the construction period and reduces the on-site labor cost.

A. Save the labor cost of scaffolding and formwork support;

B. The amount of on-site reinforcement binding is reduced by 60%~70%, reducing labor and man-hours;

C. It can provide a working platform for multiple types of work, multi-type three-dimensional construction, multi-layer simultaneous pouring, shorten the construction period and reduce costs;

D. In the later stage, the comprehensive cost is calculated without considering the cost of fire prevention and corrosion, which is more economical than the neck slab.

2. Convenience:

1. The steel truss floor bearing plate is light in weight, easy to handle, stack and install;

2. Steel bar cutting, sizing, sizing, and binding are completed in the factory to reduce the on-site workload;

3. The stress mode provides greater stiffness, reduces temporary support, and greatly improves the construction speed.

3. Reliable:

1. The force mode is reasonable, the self-weight of the floor slab is borne by the steel bar, and there is no tensile stress in the concrete, which reduces the cracks in the use stage;

2. The assembly line in the factory ensures that the steel bars are arranged evenly, the spacing of the steel bars and the position of the upper and lower steel bars are fixed accurately, and they will not be displaced during pouring, so as to ensure the thickness of the upper and lower concrete protective layers;

3. Steel truss floor bearing plate, truss size is adjustable, two-way reinforcement can be realized, without increasing the thickness of the floor slab. Suitable for all types, especially irregular floor structures;

4. The welding quality of the stud and the bottom die is easier to guarantee.

4. Security:

1. The mechanical properties are basically the same as those of traditional cast-in-place floor slabs, and they are not easy to crack;

2. The refractory steel bar is wrapped in concrete, which is equivalent to a cast-in-place floor slab, and no fire resistance test report is required (1.68 hours to verify the fire resistance of 100mm thick floor slab;

3. The bottom mold does not replace the stressed steel bar in the use stage, and there is no need to consider anti-corrosion;

4. The two-way stiffness is about the same, which is conducive to seismic resistance.

Fifth, easy to paint:

The reason why people call it steel truss floor deck is because it can be colored with various colors of paint, so as to meet the color requirements of steel. The ease of coloring is its unique advantage, which directly increases its market share. Everyone has a different preference for color. People can choose steel steel truss floor decks according to their preferences, so as to form a good environment and bring more enjoyment to people's lives.

Related News

Beijing Lichengda Corrugated Steel Steel Structure Co., Ltd.

Beijing Lichengda Corrugated Steel Stru'cture Co., Ltd.

Head office: No. 668, Wang Hua Village, Huairou Town, Huairou District, Beijing

Branch: Lilanshi Town, Yongqing County, Langfang City, Hebei Province

Quick Links

Follow us

Message

Message  tlxs1472@163.com

tlxs1472@163.com 18610556803

18610556803