NEWS CENTER

What are the advantages of steel truss floor decks?

2022-11-11

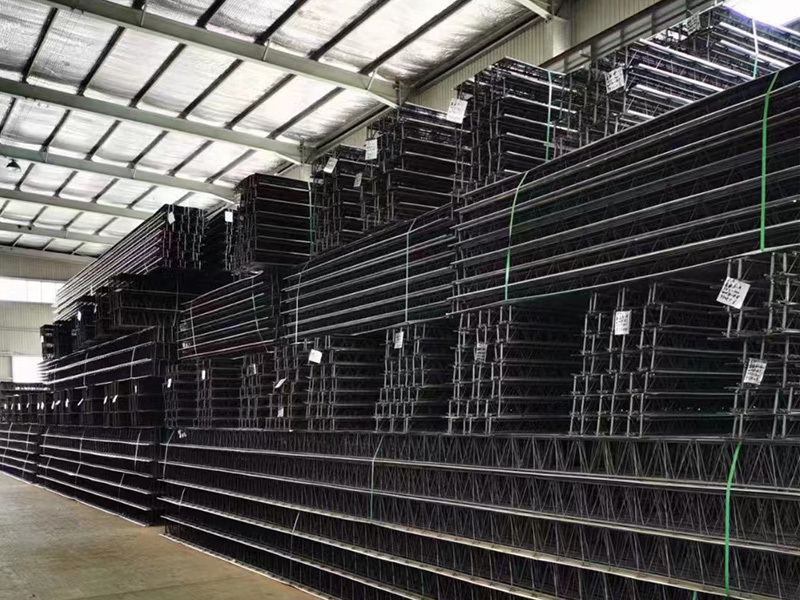

The steel truss floor deck is composed of steel bars, trusses and floor slabs, which is improved on the basis of the profiled floor slab. It can be said to be a new type of building material. The steel trusses are formed and processed in a back-end processing plant and can be prefabricated to length. Adopt sheet metal welding, silanization, pure manganese phosphating, washing and drying, galvanizing and other rust removal and rust prevention technologies, and wrap anti-rust film sealing. On-site construction requires placing the truss floor slab in the correct position, welding the steel bars, then welding the poles, and then placing the on-site steel bars for binding, and then pouring concrete after passing the acceptance.

The steel truss floor deck is a kind of unsupported special-shaped composite floor. The steel trusses will be formed and processed in the factory in the background. During on-site construction, it is necessary to fix the profiled steel plate on the steel beam with bolts, and then place the steel truss for binding, and then pour concrete after passing the acceptance. It can be said that the mechanized production has been realized, which is also conducive to the uniform spacing of steel bars and the uniform thickness of the concrete protective layer, so as to improve the construction quality of the floor slab.

Reinforced truss floor decks

Several advantages of reinforced truss floor decks

1. The steel bars are evenly arranged and the force mode is reasonable, which can greatly reduce the temporary support.

2. Double discount edge lap design, effective combination of formwork, to ensure the quality of construction.

3. The on-site steel binding workload is reduced by 60%~70%, which further shortens the construction period.

4. The mechanical properties and fire resistance are the same as those of traditional cast-in-place buildings, and there is no need to consider fire prevention and anti-corrosion issues when the bed mold is not involved in the use stage.

The steel truss floor bearing plate can significantly reduce the amount of steel binding on site, thereby speeding up the construction progress, increasing the construction safety guarantee, and realizing civilized construction. The assembly formwork and connectors are easy to disassemble and assemble, can be reused many times, saves steel, and is more in line with the national energy conservation and environmental protection requirements. All properties can meet the bearing capacity and deformation requirements of cast-in-place reinforced concrete floor slabs. Of course, there is also an unavoidable disadvantage, which is that it is easy to be damaged during transportation.

What aspects need to be paid attention to in the construction of steel truss floor deck?

1. Generally, it needs to be installed layer by layer in a bottom-up order. When the floor slabs of each floor are transported in place by crane, the top floor slabs should be installed and laid first, so that the installation safety and rainy days will be more convenient.

2. The process should be based on the starting edge of the mother buckle of the floor slab, and then start laying in turn. During the laying process, each floor load-bearing slab should be positioned according to its effective width, and the block should be positioned while laying. The surface of the beam should be welded with bolts, and the center of the bottom groove should coincide with the center of the flange.

3. The bottom plate of the column or the connecting part of the beam with the column should be cut or punched. It is recommended to cut with a plasma cutting machine, or you can choose other cutting methods agreed by the owner or supervisor.

4. When the floor slab is sealed, the baffle is set or the baffle is reinforced, the concrete should be poured according to the schedule requirements, and it needs to be completed on time.

Related News

Beijing Lichengda Corrugated Steel Steel Structure Co., Ltd.

Beijing Lichengda Corrugated Steel Stru'cture Co., Ltd.

Head office: No. 668, Wang Hua Village, Huairou Town, Huairou District, Beijing

Branch: Lilanshi Town, Yongqing County, Langfang City, Hebei Province

Quick Links

Follow us

Message

Message  tlxs1472@163.com

tlxs1472@163.com 18610556803

18610556803